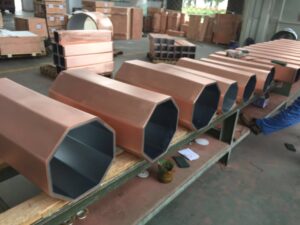

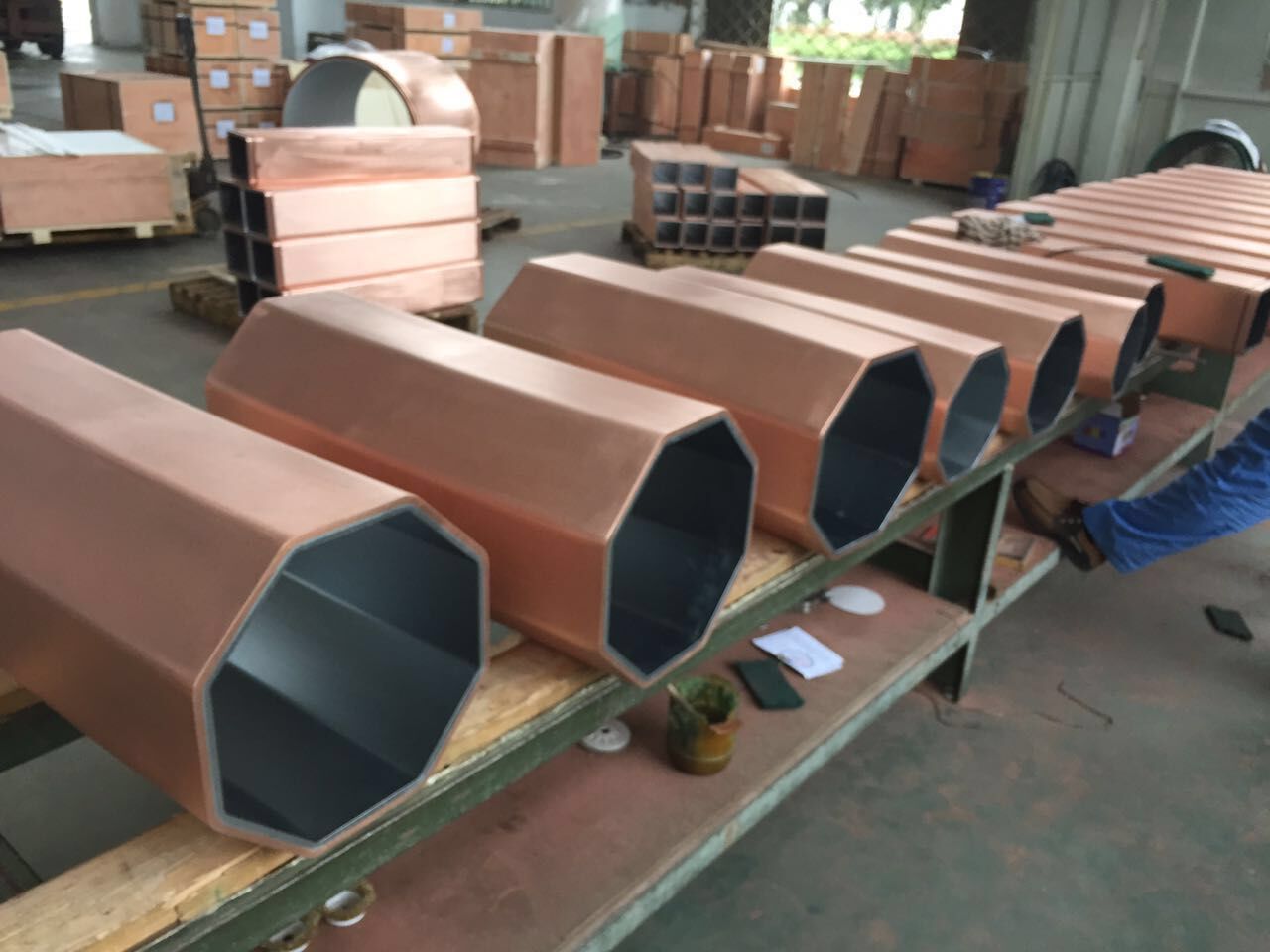

MOULD MATERIAL

TP2 is a kind of material is selected by most of the steel plants.It shows excellent heat-proof and anti-fatigue property under high temperature and it has good processing property.

CuAg0.1 with 0.08%-0.12% silver during copper ingots melting will increase the recrystallization temperature of copper by 100C, which will increase the heat stress and anti-abrasive property of copper mould tube interior surface, showing better heat resistant property than TP2.

Cu-Cr-Zr is a kind of copper alloys which can be normalized by time.It has excellent mechanical property under both room temperature and hight temperature. It has hight heat conductivity, melting point, anti-fatigue and anti heat stress properties. Their outstanding features make it different from the previous copper alloys. It combines all good properties together. But compared with other copper alloys, Cu-Cr-Zr is difficult to be formed with higher products costs.

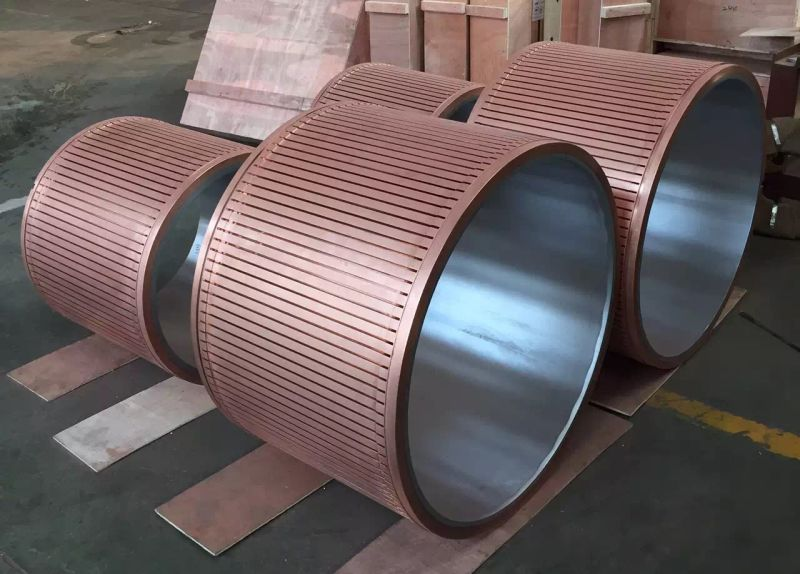

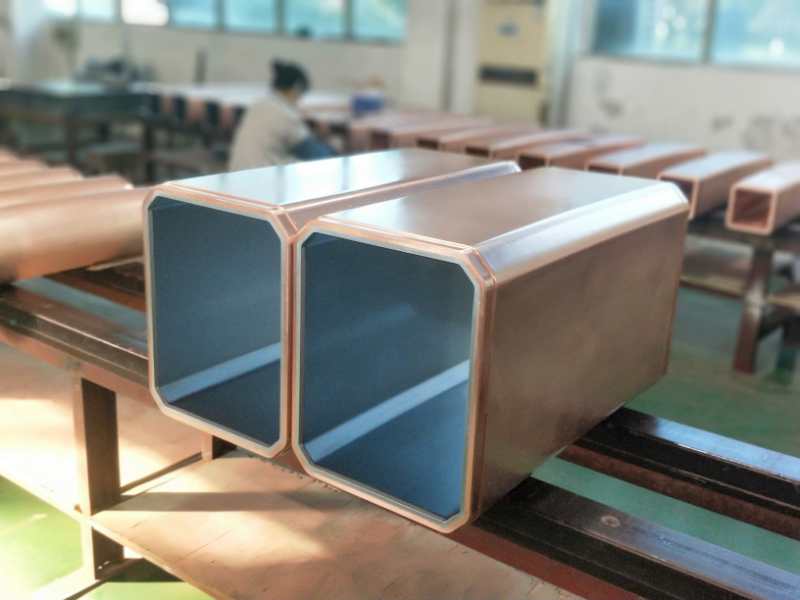

MOULD PLATE COATING

Copper has lower hardness which leads to lower anti-abrasive property. Therefore, the area at the lower part of the moulds, where the stress increases drastically due to shells, will be more severely worn. To increase the life time of copper moulds, CCM provides uniform mould interior surface plating with suitable hardness. Most of the copper mould tubes for small size billet casting are not used in any casting system where there are rigid casting stream support, therefore they are very sensitive to be worn. We use hard chrome plating to increase the life of mould tubes. The plating thickness recommended by CCM will be controlled in the best range. As for the coating of copper mould plates, based on our years of experience, we are able to provide Cr coating, Ni-Cr coating, Ni-Fe coating and Ni-Cr coating to meet the demand of various customers both at home and abroad.