Thermal Treatment Equipment

RELIANT EXIM & CONSULTING LLC is equipped with NC resistance-type furnaces, high and low temperature heat treatment furnaces, coating and quenching equipment, open-type differential temperature heat treatment furnaces, and gas baking ovens. All thermal treatment equipment utilizes computer-aided centralized control systems to provide consistent and proportional temperatures for the furnaces and to ensure dependable roll hardness.

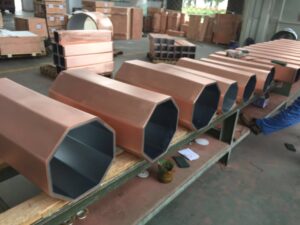

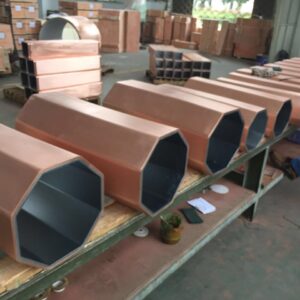

Processing Equipment

RELIANT EXIM & CONSULTING LLC processing & machining shop consists of various machining and finishing equipment: CNC Grinding Machines, CNC Lathe Machines, NC Planer Machines, Double Sided Milling Machines, and over 100 dedicated lathes for various rolls of C61250, C61200, C61125, C84180, C8463, C8440, C91250, etc. Our machining shop is equipped with various high precision cutting and processing equipment clubbed with high skilled and experienced work force guaranteeing machining and finishing accuracy of each of our rolls.

Test and Inspection Equipment

RELIANT EXIM & CONSULTING LLC has an established and error proof quality monitoring and inspection system for complete roll manufacturing process starting from raw materials to the finished goods. With high-skilled quality technicians & engineers and use of advanced inspection and test equipment to collect data and process feedback through computerized processes we achieve superior accuracy along each step and defect free final product.

RELIANT EXIM & CONSULTING LLC incorporates a Raw Material Analysis Center, a Quick Analysis Center, and a Physical Test Center to satisfy all quality testing and inspection needs for the roll manufacturing process. Using the above and inline testing for various steps we control error occurrences and early defect identification. We have strong metrics of error prevention and QC check at each stage of the manufacturing process.

RELIANT EXIM & CONSULTING LLC provides advanced measures for performance & quality control and technical research & development.

Our Raw Material Analysis Centre is equipped with a Chemical Analysis Lab, Moulding Sand Testers, Moulding Sand Hardness Metres, Coating Tester, etc.

The Quick Analysis Centre is equipped with the Leco CS230 Carbon-Sulphur Analyzer, Leco TCH Hydrogen, Oxygen Analyzer and Nitrogen Analyzer, Bruker Germany Q8 Direct Reading Spectrometer, and the OBOB GS 1000 Direct-Reading Spectrometer.

The Physical Test Center is equipped with Universal Material Testers, Impact Test Machines, Brinell & Rockwell Hardness Metre, SHIMADZU MNV-2T Metallurgical Phase Microscope, Leica DM2500M Front- View Metallurgical Phase Microscope, DM6000M Metallographic Image Analyzer, SHIMADZU Thermal Dilatometer, JSM-6150-A Scanning Electron Microscope, KK USD12 Ultrasonic Flaw Detector, etc.

| Designation of Rolls | Material Code | C % | Si % | Mn % | Ni % | Cr % | Mo % | V % | W % | ||||||

| HSS | HSS | 1.50 – 2.20 | 0.30 – 1.00 | 0.40 – 1.20 | 0.00 – 1.50 | 3.00 – 8.00 | 2.00 – 8.00 | 2.00 – 9.00 | 0.00 – 2.00 | ||||||

| S – HSS | S – HSS | 0.60 – 1.20 | 0.80 – 1.50 | 0.50 – 1.00 | 0.20 – 1.20 | 3.00 – 9.00 | 2.00 – 5.00 | 0.40 – 3.00 | 0.00 – 3.00 | ||||||

| Designation of Rolls | Material Code | C % | Si % | Mn % | Ni % | Cr % | Mo % | Mg % | |||||||

| CrMo indefinite chilled SG cast iron rolls | SG II | 3.00 - 3.40 | 1.40 - 1.90 | 0.20 - 0.80 | 0.20 - 0.60 | 0.20 - 0.60 | ≥ 0.40 | ||||||||

| NiCrMo indefinite chilled SG cast iron rolls (I) | SG IV | 3.00 - 3.40 | 1.40 - 1.90 | 0.40 - 0.80 | 0.50 - 1.00 | 0.20 - 0.60 | 0.20 - 0.60 | ≥ 0.40 | |||||||

| NiCrMo indefinite chilled SG cast iron rolls (II) | SG V | 3.00 - 3.40 | 1.40 - 1.90 | 0.40 - 0.80 | 1.10 - 2.00 | 0.30 - 1.00 | 0.20 - 0.60 | ≥ 0.40 | |||||||

| Physical Properties | |||||||||||||||

| Designation of Rolls | Material Code | Barrel Hardness HSD | Neck Hardness HSD | Tensile Strength Mpa | |||||||||||

| CrMo indefinite chilled SG cast iron rolls | SG II | 50 - 70 | 35 - 55 | >320 | |||||||||||

| NiCrMo indefinite chilled SG cast iron rolls (I) | SG IV | 55 - 70 | 35 - 55 | >320 | |||||||||||

| NiCrMo indefinite chilled SG cast iron rolls (II) | SG V | 60 - 70 | 35 - 55 | >320 | |||||||||||

| Microstructure | |||||||||||||||

| Designation of Rolls | Material Code | Microstructure | |||||||||||||

| CrMo Indefinite chilled SG cast iron rolls | SG II | Pearlite + Cementite + Small Graphite | |||||||||||||

| NiCrMo indefinite chilled SG cast iron rolls (I) | SG IV | Pearlite + Cementite + Small Graphite | |||||||||||||

| NiCrMo indefinite chilled SG cast iron rolls (II) | SG V | Fine Pearlite + Cementite + Small Graphite | |||||||||||||

| Application | |||||||||||||||

| Designation of Rolls | Material Code | Application | |||||||||||||

| CrMo indefinite chilled SG cast iron rolls | SG II | Profiles, rods, wire, and narrow strip mill thick, in the rolling mill stand | |||||||||||||

| NiCrMo indefinite chilled SG cast iron rolls (I) | SG IV | Profiles, rods, wire, and narrow strip mill thick, in the rolling mill stand | |||||||||||||

| NiCrMo indefinite chilled SG cast iron rolls (II) | SG V | Profiles, rods, wire, and narrow strip mill thick, in the rolling mill stand | |||||||||||||

| Scope of supply Barrel diameter ≤ 1000 mm Barrel length ≤ 3000 mm | |||||||||||||||

| Alloy Cast Steel Rolls Chemical Analysis | |||||||||||||||

| Designation of Rolls | Material Code | C % | Si % | Mn % | Ni % | Cr % | Mo % | ||||||||

| Zu60CrMoMn | AS60 | 0.55 – 0.65 | 0.20 – 0.45 | 0.90 – 1.20 | 0.80 – 1.20 | 0.20 – 0.45 | |||||||||

| Zu60CrMoMnNi | AS60 I | 0.55 – 0.65 | 0.20 – 0.60 | 0.50 – 1.00 | 0.20 – 1.50 | 0.80 – 1.20 | 0.20 – 0.60 | ||||||||

| Zu65CrNiMo | AS65 I | 0.60 – 0.70 | 0.20 – 0.60 | 0.50 – 0.80 | 0.20 – 0.50 | 0.80 – 1.20 | 0.20 – 0.45 | ||||||||

| Zu70Mn | AS70 | 0.65 – 0.75 | 0.20 – 0.45 | 0.80 – 1.40 | |||||||||||

| Zu70Mn2 | AS70 I | 0.65 – 0.75 | 0.20 – 0.45 | 1.40 – 1.80 | |||||||||||

| Zu70Mn2Mo | AS70 II | 0.65 – 0.75 | 0.20 – 0.45 | 1.40 – 1.80 | 0.20 – 0.45 | ||||||||||

| Zu75CrMo | AS75 | 0.70 – 0.80 | 0.20 – 0.45 | 0.60 – 0.90 | 0.75 – 1.00 | 0.20 – 0.45 | |||||||||

| Zu75CrNiMnMo | AS75 I | 0.70 – 0.80 | 0.20 – 0.70 | 0.70 – 1.10 | ≥ 0.20 | 0.80 – 1.50 | 0.20 – 0.60 | ||||||||

| Physical Properties | |||||||||||||||

| Designation of Rolls | Material Code | Barrel Hardness HSD | Neck Hardness HSD | Tensile Strength Mpa | |||||||||||

| Zu60CrMoMn | AS60 | 35 – 50 | ≤ 45 | > 650 | |||||||||||

| Zu60CrMoMnNi | AS60 I | 35 – 45 | ≤ 45 | > 750 | |||||||||||

| Zu65CrNiMo | AS65 I | 35 - 45 | ≤ 45 | > 750 | |||||||||||

| Zu70Mn | AS70 | 32 - 42 | ≤ 45 | > 650 | |||||||||||

| Zu70Mn2 | AS70 I | 35 - 45 | ≤ 45 | > 680 | |||||||||||

| Zu70Mn2Mo | AS70 II | 35 - 45 | ≤ 45 | > 700 | |||||||||||

| Zu75CrMo | AS75 | 35 - 50 | ≤ 45 | > 700 | |||||||||||

| Zu75CrNiMnMo | AS75 I | 35 – 50 | ≤ 45 | > 800 | |||||||||||

| Microstructure Microstructure of working layer in the barrel: pearlite or tempered sorbite Application | |||||||||||||||

| Designation of Rolls | Material Code | Application | |||||||||||||

| Zu60CrMoMn | AS60 | Bar, wire, strip, steel roughing | |||||||||||||

| Zu60CrMoMnNi | AS60 I | Bar, wire, strip, steel roughing | |||||||||||||

| Zu65CrNiMo | AS65 I | Bar, wire, strip, steel roughing | |||||||||||||

| Zu70Mn | AS70 | Bar, wire, strip, steel roughing | |||||||||||||

| Zu70Mn2 | AS70 I | Bar, wire, strip, steel roughing | |||||||||||||

| Zu70Mn2Mo | AS70 II | Bar, wire, strip, steel roughing | |||||||||||||

| Zu75CrMo | AS75 | Bar, wire, strip, steel rough rolling, narrow steel support rollers | |||||||||||||

| Zu75CrNiMnMo | AS75 I | Bar, wire, strip, steel rough rolling, narrow steel support rollers | |||||||||||||

| Scope of Supply:-Barrel diameter ≤ 1000 mm / Barrel length ≤ 3000 mm | |||||||||||||||

| Pearlitic Ductile Cast Iron Rolls Chemical Analysis | |||||||||||||||

| Designation of Rolls | Material Code | C % | Si % | Mn % | Ni % | Cr % | Mo % | Mg % | |||||||

| Pearlitic ductile cast iron roll I | SGP I | 3.00 – 3.40 | 1.40 – 1.90 | 0.40 – 0.80 | 1.50 – 2.00 | 0.20 – 0.60 | 0.20 – 0.60 | ≥ 0.04 | |||||||

| Pearlitic ductile cast iron roll II | SGP II | 3.00 – 3.40 | 1.20 – 2.00 | 0.40 – 0.80 | 2.01 – 2.50 | 0.20 – 1.00 | 0.20 – 0.60 | ≥ 0.04 | |||||||

| Pearlitic ductile cast iron roll III | SGP III | 3.00 – 3.40 | 1.00 – 2.00 | 0.40 – 0.80 | 2.51 – 3.00 | 0.20 – 1.20 | 0.20 – 0.60 | ≥ 0.04 | |||||||

| Physical Properties | |||||||||||||||

| Designation of Rolls | Material Code | Barrel Hardness HSD | Neck Hardness HSD | Tensile strength Mpa | |||||||||||

| Pearlitic ductile cast iron roll I | SGP I | 45 – 55 | 35 – 55 | >450 | |||||||||||

| Pearlitic ductile cast iron roll II | SGP II | 55 – 65 | 35 – 55 | >450 | |||||||||||

| Pearlitic ductile cast iron roll III | SGP III | 62 – 72 | 35 – 55 | >450 | |||||||||||

| Microstructure | |||||||||||||||

| Designation of Rolls | Material Code | Microstructure | |||||||||||||

| Pearlitic ductile cast iron roll I | SGP I | Pearlite + Cementite + Small Graphite | |||||||||||||

| Pearlitic ductile cast iron roll II | SGP II | Pearlite + Cementite + Small Graphite | |||||||||||||

| Pearlitic ductile cast iron roll III | SGP III | Globular Pearlite + Carbide + Graphite or small amount of pearlite + Bainite + Carbide + Spherical Graphite | |||||||||||||

| Application | |||||||||||||||

| Designation of Rolls | Material Code | Application | |||||||||||||

| Pearlitic ductile cast iron roll I | SGP I | Profiles, rods, wire and narrow strip mill thick, in the rolling mill stand | |||||||||||||

| Pearlitic ductile cast iron roll II | SGP II | Profiles, rods, wire and narrow strip mill thick, in the rolling mill stand | |||||||||||||

| Pearlitic ductile cast iron roll III | SGP III | Profiles, rods, wire and narrow strip mill thick, in the rolling mill stand | |||||||||||||

| Scope of supply Barrel diameter ≤ 1000 mm Barrel length ≤ 3000 mm |