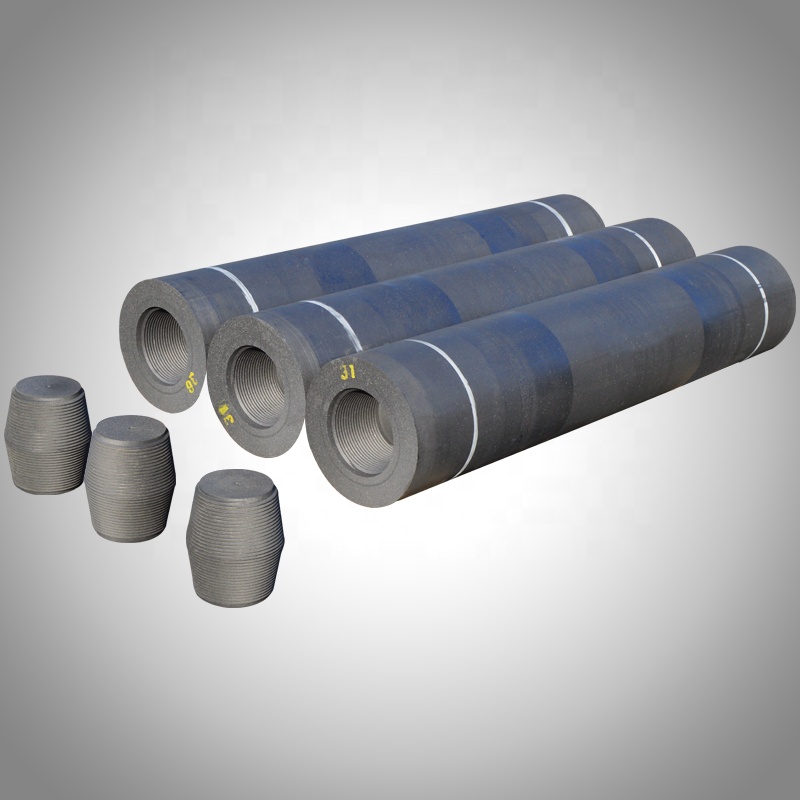

Features

- High bulk density, precision thread accuracy.

- Check the tolerance of nipples one by one.

- Bending strength limits are measured.

- High machining accuracy, good surface finishing.

- Outstanding resistance to breakage.

- Original factory production, not outsourcing.

Specification

| Item | Resistance | Density | Flexure Strength | Elastic Modulus | Ash Content | CTE |

| (≤, µΩ·m) | (≥, g/cm3) | (≥, MPa) | (≤, GPa) | (≤, %) | (100 °C – 600 °C) |

| | | | | | (≤, 10-6/°C) |

| Regular power | 6 | 1.72 | 15 | 14 | 0.3 | 2.5 |

| High Power | 5 | 1.75 | 18 | 18 | 0.3 | 2.2 |

| Ultra High Power | 4.2 | 1.78 | 20 | 22 | 0.3 | 1.4 |

Dimensions of Nipple & Sockets (TPI 3)

| Electrode Dia. | | Nipple Designation | Nipple | | Socket | | |

| | | Major Dia. | Length | Pitch Dia. | Depth | Thread Length |

| | | (mm) | (mm) | (mm) | (mm) | (mm) |

| (inch) | (mm) | | d1 | l1 | d4 | l2 | l3 |

| 9 | 225 | 139T3N | 139.7 | 203.2 | 135.49 | 107.6 | 103.6 |

| 10 | 250 | 155T3N | 155.57 | 220 | 151.36 | 116 | 112 |

| 12 | 300 | 177T3N | 177.16 | 270.9 | 172.95 | 141.5 | 137.5 |

| 14/16 | 350/400 | 215T3N | 215.9 | 304.8 | 211.69 | 158.4 | 154.4 |

| 14/16 | 350/400 | 215T3L | 215.9 | 355.6 | 211.69 | 183.8 | 179.8 |

| 16/18 | 400/450 | 241T3N | 241.3 | 338.7 | 237.09 | 175.3 | 171.3 |

| 16/18 | 400/450 | 241T3L | 241.3 | 355.6 | 237.09 | 183.8 | 179.8 |

| 20 | 500 | 273T3N | 273.05 | 355.6 | 268.84 | 183.8 | 179.8 |

| 20 | 500 | 273T3L | 273.05 | 457.2 | 268.84 | 234.6 | 230.6 |

| 22 | 550 | 298T3L | 298.45 | 457.2 | 294.24 | 234.6 | 230.6 |

* Pin pitch diameter d2 is equal to socket pitch diameter d4.

* Socket minor diameter d3 is equal to pitch diameter d4 minus 3.16 mm.

* Other combinations of nominal diameter and joint are to be agreed upon between the supplier and user.

Dimensions of Nipple & Sockets (TPI 4)

| Electrode Dia. | | Nipple Designation | Nipple | | Socket | | |

| | | Major Dia. | Length | Pitch Dia. | Depth | Thread Length |

| | | (mm) | (mm) | (mm) | (mm) | (mm) |

| (inch) | (mm) | | d1 | l1 | d4 | l2 | l3 |

| 9 | 225 | 139T4N | 139.7 | 177.8 | 136.54 | 94.9 | 90.9 |

| 10 | 250 | 152T4N | 152.4 | 190.5 | 149.24 | 101.3 | 97.3 |

| 12 | 300 | 177T4N | 177.8 | 215.9 | 174.64 | 114 | 110 |

| 14 | 350 | 203T4N | 203.2 | 254 | 200.04 | 133 | 129 |

| 14 | 350 | 203T4L | 203.2 | 304.8 | 200.04 | 158.4 | 154.4 |

| 16 | 400 | 222T4N | 222.25 | 304.8 | 219.09 | 158.4 | 154.4 |

| 16 | 400 | 222T4L | 222.25 | 355.6 | 219.09 | 183.8 | 179.8 |

| 18 | 450 | 241T4N | 241.3 | 304.8 | 238.14 | 158.4 | 230.6 |

| 18 | 450 | 241T4L | 241.3 | 355.6 | 238.14 | 183.8 | 179.8 |

| 20 | 500 | 269T4N | 269.88 | 355.6 | 266.72 | 183.8 | 179.8 |

| 20 | 500 | 269T4L | 269.88 | 457.2 | 266.72 | 234.6 | 230.6 |

| 22 | 550 | 298T4N | 298.45 | 355.6 | 295.29 | 183.8 | 179.8 |

| 22 | 550 | 298T4L | 298.45 | 457.2 | 295.29 | 234.6 | 230.6 |

| 24 | 600 | 317T4N | 317.5 | 355.6 | 314.34 | 183.8 | 179.8 |

| 24 | 600 | 317T4L | 317.5 | 457.2 | 314.34 | 234.6 | 230.6 |

* Pin pitch diameter d2 is equal to socket pitch diameter d4.

* Socket minor diameter d3 is equal to pitch diameter d4 minus 3.16 mm.

* Other combinations of nominal diameter and joint are to be agreed upon between the supplier and user.

Standard Electrode Sizes & Nipple Weights

| Electrode | | Standard Weight of Nipples | | | | | | | |

| Nominal Electrode Size | | TPI 3 | | | | TPI 4 | | | |

| Dia. × L | | T3N | | T3L | | T4N | | T4L | |

| inch | mm | lbs | kg | lbs | kg | lbs | kg | lbs | kg |

| 14 × 72 | 350 × 1800 | 32 | 14.5 | - | - | 24.3 | 11 | - | - |

| 16 × 72 | 400 × 1800 | 45.2 | 20.5 | 46.3 | 21 | 35.3 | 16 | 39.7 | 18 |

| 16 × 96 | 400 × 2400 | 45.2 | 20.5 | 46.3 | 21 | 35.3 | 16 | 39.7 | 18 |

| 18 × 72 | 450 × 1800 | 62.8 | 28.5 | 75 | 34 | 41.9 | 19 | 48.5 | 22 |

| 18 × 96 | 450 × 2400 | 62.8 | 28.5 | 75 | 34 | 41.9 | 19 | 48.5 | 22 |

| 20 × 72 | 500 × 1800 | 79.4 | 36 | 93.7 | 42.5 | 61.7 | 28 | 75 | 34 |

| 20 × 84 | 500 × 2100 | 79.4 | 36 | 93.7 | 42.5 | 61.7 | 28 | 75 | 34 |

| 20 × 96 | 500 × 2400 | 79.4 | 36 | 93.7 | 42.5 | 61.7 | 28 | 75 | 34 |

| 20 × 110 | 500 × 2700 | 79.4 | 36 | 93.7 | 42.5 | 61.7 | 28 | 75 | 34 |

| 22 × 84 | 550 × 2100 | - | - | - | - | 73.4 | 33.3 | 94.8 | 43 |

| 22 × 96 | 550 × 2400 | - | - | - | - | 73.4 | 33.3 | 94.8 | 43 |

| 24 × 84 | 600 × 2100 | - | - | - | - | 88.2 | 40 | 110.2 | 50 |

| 24 × 96 | 600 × 2400 | - | - | - | - | 88.2 | 40 | 110.2 | 50 |

| 24 × 110 | 600 × 2700 | - | - | - | - | 88.2 | 40 | 110.2 | 50 |

Coupling Torque Reference for Nipple & Electrode

| Electrode Diameter | inch | 8 | 9 | 10 | 12 | 14 | 16 | 18 | 20 | 22 | 24 |

| mm | 200 | 225 | 250 | 300 | 350 | 400 | 450 | 500 | 550 | 600 |

| Easing Moment | N.m | 200–260 | 300–340 | 400–450 | 550–650 | 800–950 | 900–1100 | 1100–1400 | 1500–2000 | 1900–2500 | 2400–3000 |

Below chart is the matching relationship between electric furnace capacity, transformer power load and electrode size.

| Furnace Capacity | Inner Dia. | Transformer Capacity (MVA) | | | Electrode Dia. |

| t | m | RP | HP | UHP | mm |

| 10 | 3.35 | 5 | 7.5 | 10 | 300/350 |

| 15 | 3.65 | 6 | 10 | 12 | 350 |

| 20 | 3.95 | 7.5 | 12 | 15 | 350/400 |

| 25 | 4.3 | 10 | 15 | 18 | 400 |

| 30 | 4.6 | 12 | 18 | 22 | 400/450 |

| 40 | 4.9 | 15 | 22 | 27 | 450 |

| 50 | 5.2 | 18 | 25 | 30 | 450 |

| 60 | 5.5 | 20 | 27 | 35 | 500 |

| 70 | 6.8 | 22 | 30 | 40 | 500 |

| 80 | 6.1 | 25 | 35 | 45 | 500 |

| 100 | 6.4 | 27 | 40 | 50 | 500 |

| 120 | 6.7 | 30 | 45 | 60 | 550/600 |

| 150 | 7 | 35 | 50 | 70 | 600 |

| 170 | 7.3 | - | 60 | 80 | 600 |

| 200 | 7.6 | - | 70 | 100 | 600/700 |

| 250 | 8.2 | - | - | 120 | 700 |

| 300 | 8.8 | - | - | 150 | 700 |