Technical Specification of finished Carbide Roll Rings

The allowable deviation of carbide roll rings

Radial runout of groove ≤ 0.013 mm

Radial runout of periphery ≤ 0.013 mm

End face runout ≤ 0.02 mm

End face planeness ≤ 0.01 mm

End face parallelism ≤ 0.01 mm

Roughness of carbide rolls

Inner hole roughness 0.4µm

Periphery roughness 0.8µm

End face roughness 0.4µm

The allowable deviation in external diameter, internal diameter and height is to be determined based on the customer’s needs.

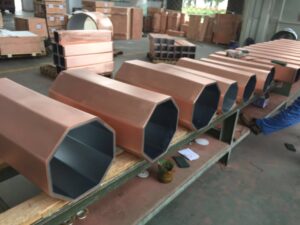

Cemented Carbide Composite Rolls

Our cemented carbide composite rolls are mainly used on the finishing mill for bar, deformed steel bar and common wire. Cemented carbide composite rolls offer reduced change over due to grooves over rolls resulting in reduced change over needs & time and hence improve work efficiency. Using these rolls will improve the surface quality & yield providing remarkable economic benefits. Assembly of the cemented carbide Rolls is quick and easy with the use of a simple hydraulic lock nut to the axial shaft. A pressure of 200 MPa is needed for the same.

Cemented Carbide Composite Rolls Specifications

| External Diameter | Width | Rolling Size |

| 285 – 480 | 50-140 | 5-28 |